C.P.A. srl is a company that operates in the luxury fashion sector, collaborating with global brands for almost 30 years. The company offers brand clients various services beyond production. It supports their designers in the design of collections and/or parts thereof, at any requested stage. From mood board and trend studies to sourcing raw materials and developing accessories, treatments, embroidery, etc., up to production.

The product office staff frequently attend the main textile fairs in the sector, seeking new suppliers of raw materials, special items, and cutting-edge technologies for their production. This way, they remain updated and proactive, assisting clients in identifying everything they need to develop their ideas.

At the client’s request, the product office can develop and create customized labels, patches, tags, bags, buttons, zippers, etc., working closely with the style office to find the most suitable suppliers, materials, and techniques.

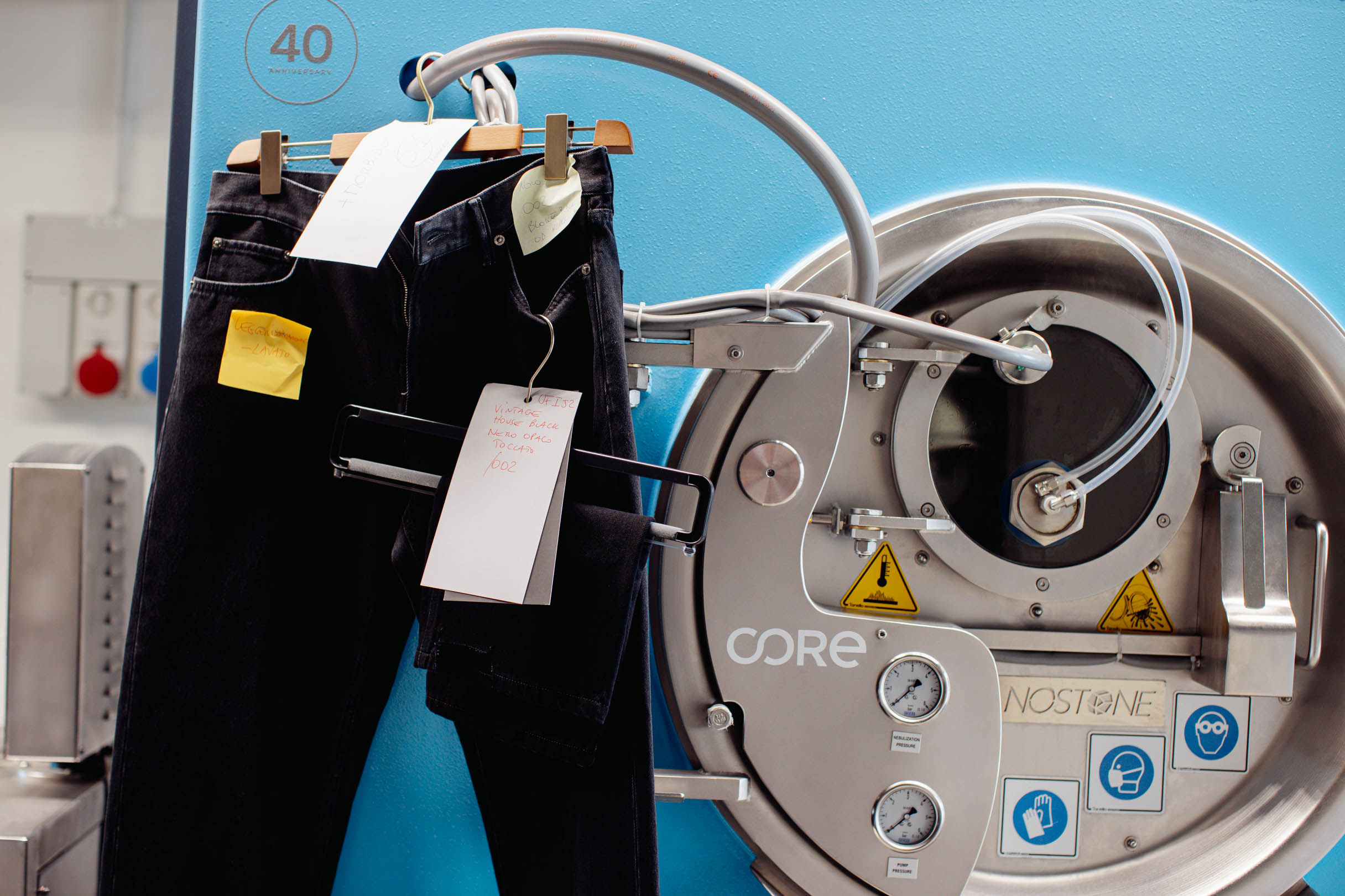

At the client’s request, our qualified staff can assist the client in researching washes and treatments for their products, whether denim, cotton, wool, nylon, silk, linen, etc.

The company has an internal archive that can be a resource for the client and continually develops new techniques to stay updated and share its knowledge with the client.

Recently, an internal laundry facility was inaugurated for researching new treatments and handling small quantities of garments or single pieces. This internal lab aims to produce custom pieces for ‘top clients’ and show pieces, developing continuous trials and new treatment techniques. For production treatments, the company relies on trusted external partners that meet high-quality standards and service requirements.

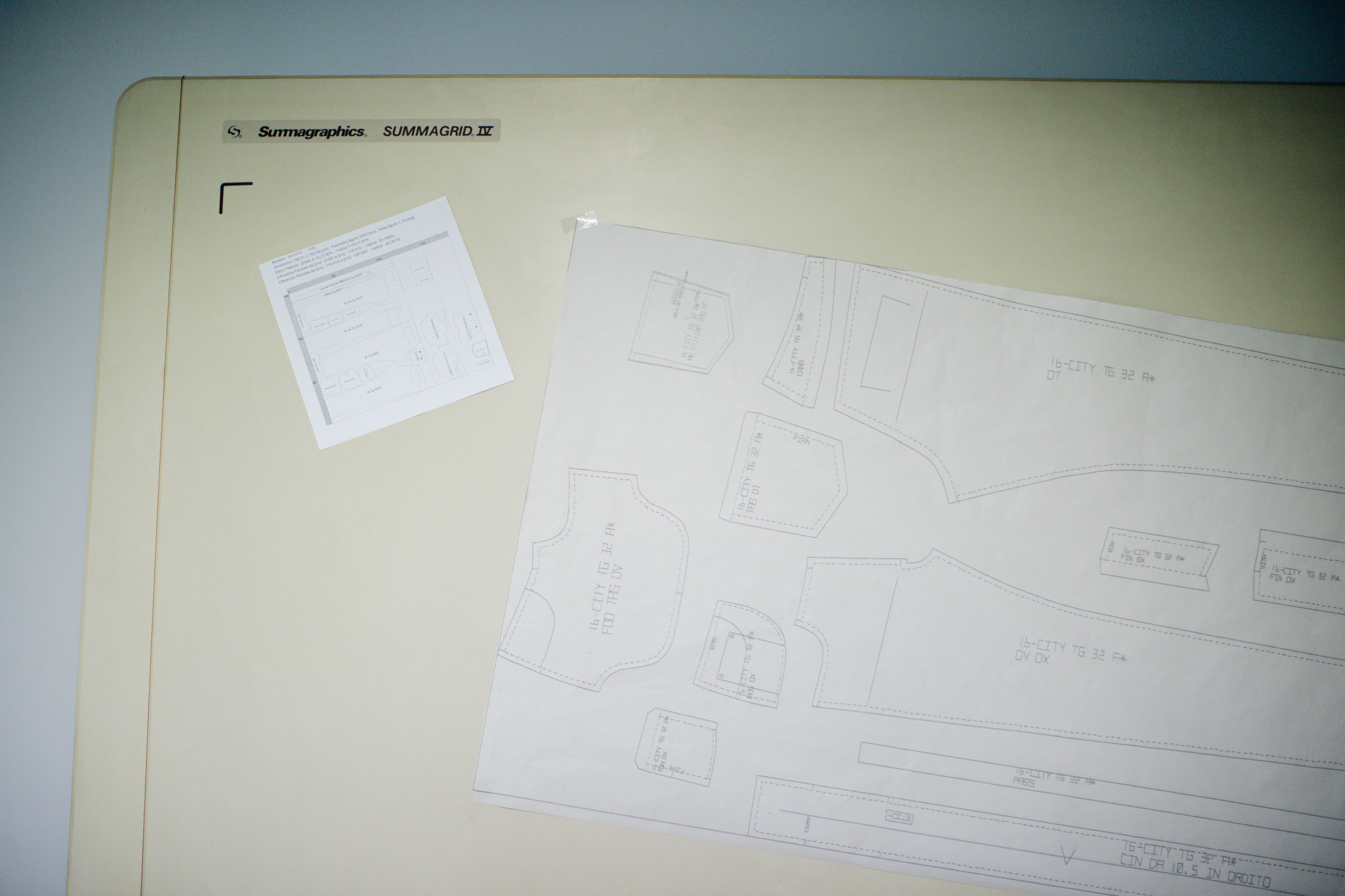

C.P.A. srl has an internal pattern-making department.

Placements for production are done internally, both automatically and manually, ensuring optimal use of raw materials and avoiding unnecessary waste. New patterns can be created based on client specifications or modifications made to existing bases.

We handle the pattern creation and the related production modifications. For specific product categories, we collaborate with external services with which we have established long-term working relationships.

The company has cutting tables for both manual and automatic work.

All prototypes, most collection sets, and part of the Made in Italy production are cut internally.

The first prototypes are sewn internally, allowing prototype makers to interface with the pattern-making department during this critical phase to identify issues or suggest improvements, ensuring extreme care at this initial stage.

The small internal lab can sew prototypes, collection sets, small productions, and custom pieces upon specific client requests.

Prototypes and collection sets are manufactured internally.

After creating the first pattern based on style instructions and manufacturing the first prototype, the client can provide feedback and request modifications, working directly with specialized staff. Following the client’s requests and applying our extensive expertise, we handle all pattern modifications or corrections.

We provide significant support during the manufacturing phase, finding the best solutions for garment industrialization.

Quality control is carried out at every stage of work. Fabrics are inspected upon arrival, cut parts are checked, garments are inspected after manufacturing, after treatment, and after ironing, convluding with inspections of 100% of the garments before delivery.

Quality testing, finalized during the ironins phase, is particularly important and delicate, conducted at every stage under the supervision of specialized company personnel.

Throughout the garment’s work process, from initial measurements and fabric indications to packaging, a technical sheet is compiled with all the information (materials, accessory instructions, sewing threads, and decorations like embroidery and prints, washing or dyeing, ironing, folding, and packaging, etc.).

At each stage, specialized staff complete internal sheets with all the information useful for production or simply archived for company and client records.

C.P.A. srl operates in luxury garment production for decades, handling commercialized, industrialized, or licensed brand productions. They purchase fabrics, accessories, and everything needed for garment production based on specific client requests, sourcing from chosen suppliers or proposing alternatives for better economy or production timing optimization.

Fabrics and accessories purchased for client productions are inspected 100% upon arrival at the warehouses. The company supports clients with all necessary export tests, it can also support clients in all necessary tests for export to specific countries, interfacing directly with analysis laboratories to ensure clients have all required documentation.

Garments are cut either in Italy or at the overseas facility, depending on where manufacturing will occur. Both facilities have advanced cutting tables and equipment.

Garments are manufactured in the internal lab or at partner laboratories under direct company supervision for Made in Italy production. In the Romanian facility, all manufacturing is done internally.

The company has internal embroidery machines.

For all types of prints (water, plastisol, flock, etc.), we rely on established external partners. Printing can be managed on semi-finished or finished garments as needed. Internal presses are available for transfer decorations.

For washing and dyeing, we collaborate with various external partners, chosen based on the required processing, within the national territory under direct company control. We can develop any type of wash or dye and offer a wide range of advanced techniques, including ozone or laser.

We have a small internal laundry for prototype development, small productions, or custom garments, using Tonello machinery and a laser for denim treatments. With ourr facilities (photovoltaic energy and water cleaning pumps), we guarantee eco-sustainable washes and 95% water reuse.

For Italian productions, ironing is partly done internally and partly by local partners under direct company supervision.

Garments are packaged internally according to client specifications using their selected packaging materials.

The facility offers a 360° service to clients, preparing goods for shipment to their warehouses and/or clients as needed.

We can also prepare shipments dividing goods by client/store or upload them to client portals/warehouses, with the necessary software and passwords if requested.

From the warehouses in the province of Venice, they deliver worldwide.

With have decades of experience in customs procedures and hold export codes for all major markets, along with the habitual exporter certificate.

Shipments can be made with folded or hanging garments, depending on the product and requirement.

In 2022, C.P.A. srl started producing custom-made garments for the top clients of the brands they collaborate with. We have always been structured to produce fashion show garments, niche productions, collection sets, etc.

Upon client request, we dedicated part of the internal lab to custom-made garment production, starting from the final client’s measurements to create or adapt a custom pattern. Using selected fabrics and accessories, unique personalized garments are produced.

This service is aimed at meeting the varied and growing demands of the luxury market in which the company has operated since its inception.

C.P.A. SRL CENTRO PRODUZIONE ABBIGLIAMENTO

Sede legale: VIA VALLETTA, 1A – 30010 CONA (VE)

Partita IVA: 02863960270

Rea: VE-246250

Capitale sociale: € 18.246

Tel 0426 302189

amministrazione@cpasrl.com

W&F

STR Victorei, 240

Maramures, 430061 Baia Mare

Romania