W&F was founded in 2001 as a production base in Romania for C.P.A. srl. The company was created for larger quantity productions for clients who do not require ‘Made in Italy’. Initially, W&F operated as an office with only Italian technicians managing local productions for C.P.A. srl, assigning them to local subcontractors. The need to ensure high-quality standards, increased production demands, and the consequent need for production space led the company to structure itself into a true production unit.

Garments to be produced are cut internally.

W&F has a facility in Baia Mare dedicated solely to fabric storage and cutting, with permanent staff and additional support when needed.

We have two tables, one automatic spreader, one automatic cutting machine, and an average cutting capacity of about 800 garments per day. There is also a nailed table for plaid cutting.

W&F sews all assigned garments internally, with an average production capacity of 500 garments per day/10,000 per month. We have advanced technology for industrial processes, including automatic pocket setters, field machines for label applications, pocket hemmers, waistband application machines, and automatic fly machines for fly stitching and design.

The Baia Mare facility has a section for prototype/sample production and has the same capacity for C.P.A. srl’s orders and clients directly supplied by the Romanian company. We can manage the entire process from pattern creation to raw material and accessory research, following the parent company’s directives. In the same department, pattern development for industrial production is done.

The company has several multi-head embroidery machines for small or large-sized and placed embroideries. It can also perform laser embroidery.

Printing is done through C.P.A. srl in Italy, both on cut and semi-finished garments.

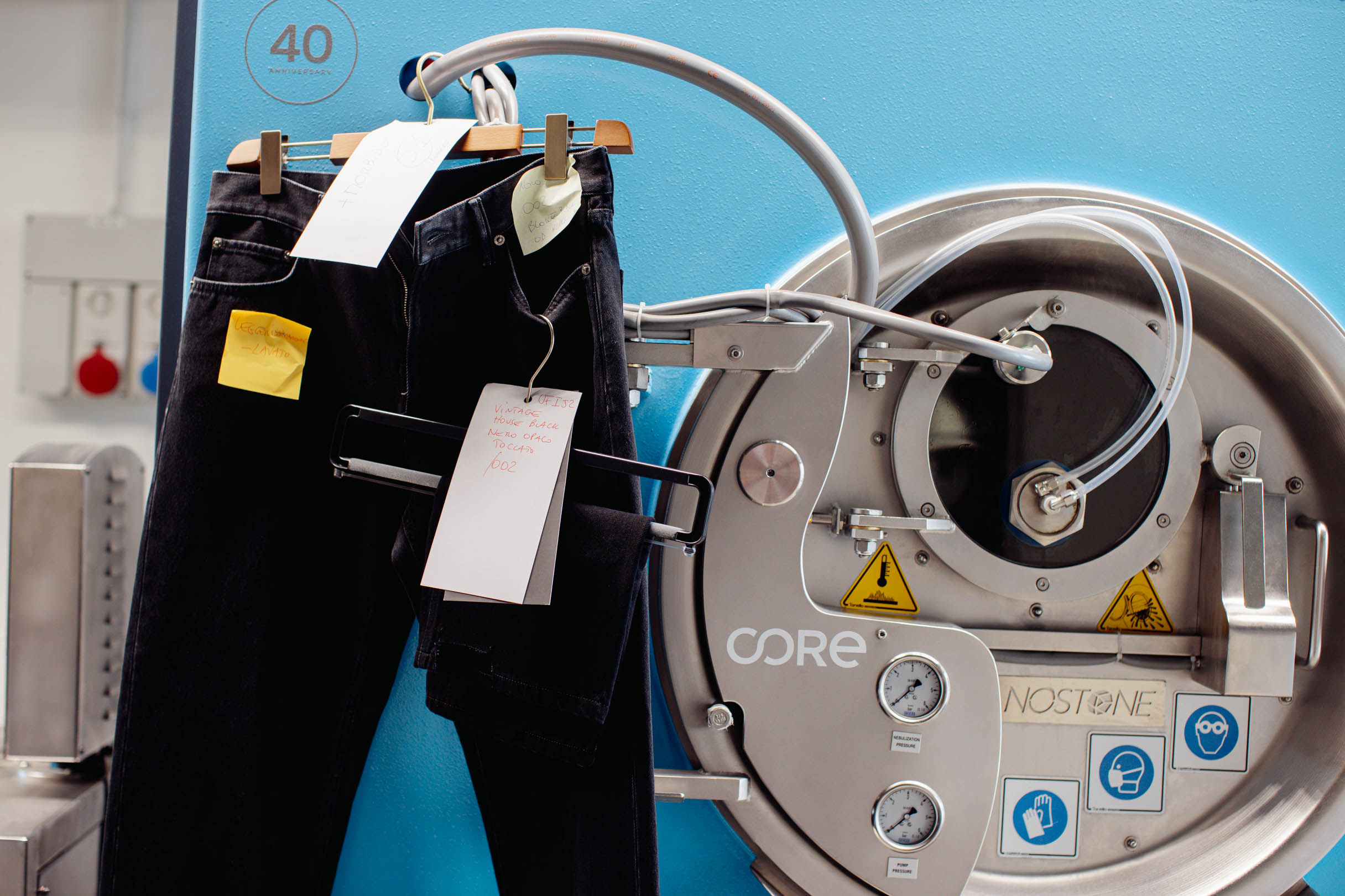

For general treatments, W&F relies on Italian laundries through C.P.A. srl, with which they have established relationships over the years, and under constant company technician supervision, personally overseeing the various treatment stages.

Transport personnel travel between Italy and Romania weekly, with the number of trips proportional to needs, ensuring some processes in Italy for Romanian productions without slowing down processes and deliveries.

The final quality check, after those at every work stage, is done during and after ironing, making it one of the first internalized phases.

The company has an internal ironing department with traditional tables and mannequins, Italian technicians from the parent company in Italy are constantly training the local staff.

The packaging department is in charge of the last controls, packaging, and shipping. They can package hanging or folded garments depending on client requests and prepare boxes with the necessary documentation for shipment. Final quality control is done in this department, following checks at each work stage. A 100% inspection of finished garments is conducted here, with direct and transparent reporting to clients, both for quality compliance and for a general view of production progress.

Clients who wish to do so can also take advantage of our storage service, with a dedicated section created in the warehouse for each client. The goods, once ready and checked, are placed in specific cartons and pallets for each client. We take care of storing the products and dividing them according to the client’s instructions, thus facilitating final logistics operations. We collaborate with national and international couriers and handle all formalities for the organization of shipments, both within Italy and abroad.

Our facilities have a loading area, even for full containers, thus facilitating the movement of goods in case of orders for productions destined abroad.

Shipments are prepared directly from the Baia Mare plant to the final client.

The company works with the main global brands, which, over the years, have entrusted the production of their garments, both denim and classic sportswear, to C.P.A. srl and W&F, with whom there is a collaboration for their production needs.

W&F is certified with the main market certifications, and their productions are subject to constant quality controls and audits, ensuring compliance with client regulations and maintaining the highest standards.

C.P.A. SRL CENTRO PRODUZIONE ABBIGLIAMENTO

Sede legale: VIA VALLETTA, 1A – 30010 CONA (VE)

Partita IVA: 02863960270

Rea: VE-246250

Capitale sociale: € 18.246

Tel 0426 302189

amministrazione@cpasrl.com

W&F

STR Victorei, 240

Maramures, 430061 Baia Mare

Romania